CST-750

Air-Over-Water Surge Control System

The magnitude of the pressure transient is a function of three parameters: changes in fluid velocity, fluid density and pressure wave speed. Pressure transients in a fluid system generally originate from pump start-up or shut-down and rapid opening and closing of valves. Transients are further magnified to damaging proportions when there are elevation changes in the fluid system. The results of water hammer and pressure pulsations can be catastrophic. Pipeline failure, pump and valve damage, loss of system control and the associated capital equipment and maintenance costs are common problems.

PULSCO’s Hydropneumatic Surge Control System designs are developed from a proprietary program developed especially for surge control analysis to model the fluid system. From this analysis, the correct surge tank and components can be sized and determined. The result is a complete and accurate account of system requirements and a reliable solution design for any transient flow problem.

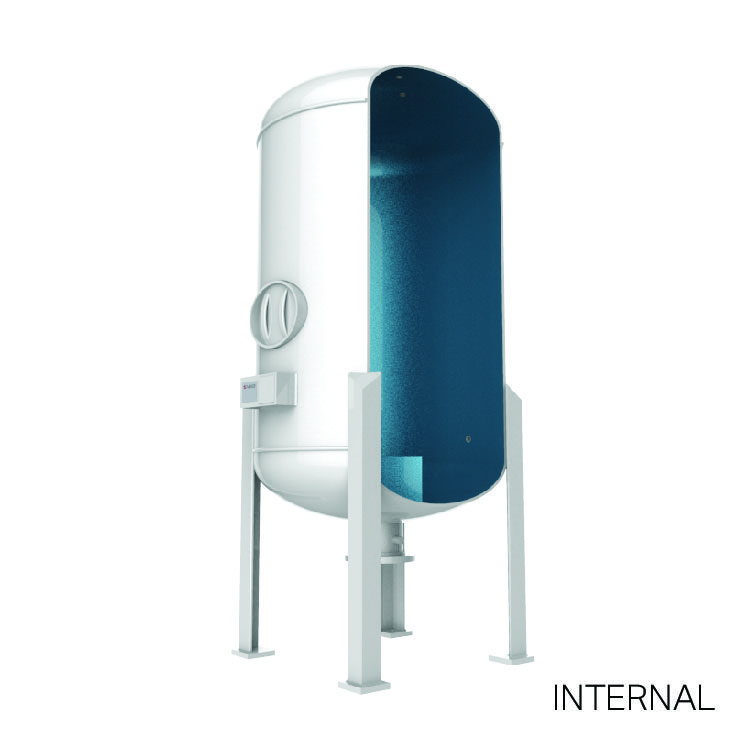

The pressure vessel is constructed to ASME, Section VIII, Div. 1 Pressure Vessel Code Requirements. The surge tank volume and design pressure is determined by the system’s requirements and horizontal or vertical arrangements are possible.

Monthly checks of the sight glass to verify normal system operation are all that is generally required. Because of positive pressure control, the PULSCO Surge Control System will permit cost savings by use of thinner wall pipe and prevent damage of costly components such as valves.

Surge Control System Operation

The principal components of the system are the hydropneumatic tank, an ASME pressure vessel, and the automatic level control system (control panel, valves, level transmitter, air compressor, and sight glass). The standard hydropneumatic tank contains no moving parts to wear out.

The surge control system controls the energy and thus minimizes transient pressure from the shock waves. Since the pressure condition in the pipeline is sensed automatically, the surge arrestor reacts immediately to a pressure decrease by discharging water to the pipeline before column separation occurs. Complete protection of the fluid system may require two surge control systems; one on the discharge side of the pump to protect the pipeline from sudden valve closure and pump start-up/shutdown, and one on the suction side of the pump to prevent cavitation on pump start-up/shutdown and eliminate surges caused by pump shutdown.

Before

Before

After

After