Vent Silencer

PULSCO Vent Silencers reduce the noise generated by the expansion of gas or steam from elevated pressures to atmospheric pressure. These absorptive silencers are used to suppress noise generated by high velocity gas streams such as steam vents, safety relief valve outlets, system blow down and purge outlets.

Our Vent Silencers are completely customizable and allow for either vertical or horizontal orientation.

Call us 949.261.1717

For any question or concern

Self-supporting bottom inlet

Flanged inlet connection

Lifting lugs

Skirt or leg supports for vertical mounting under specified loading conditions

Self-supporting bottom inlet

Flanged inlet connection

Lifting lugs

Skirt or leg supports for vertical mounting under specified loading conditions

Optional Features

Weatherhood

Saddle supports for horizontal mounting

Bird screen

Drain muffler

Special material & finishes for high temperature and/or corrosive applications.

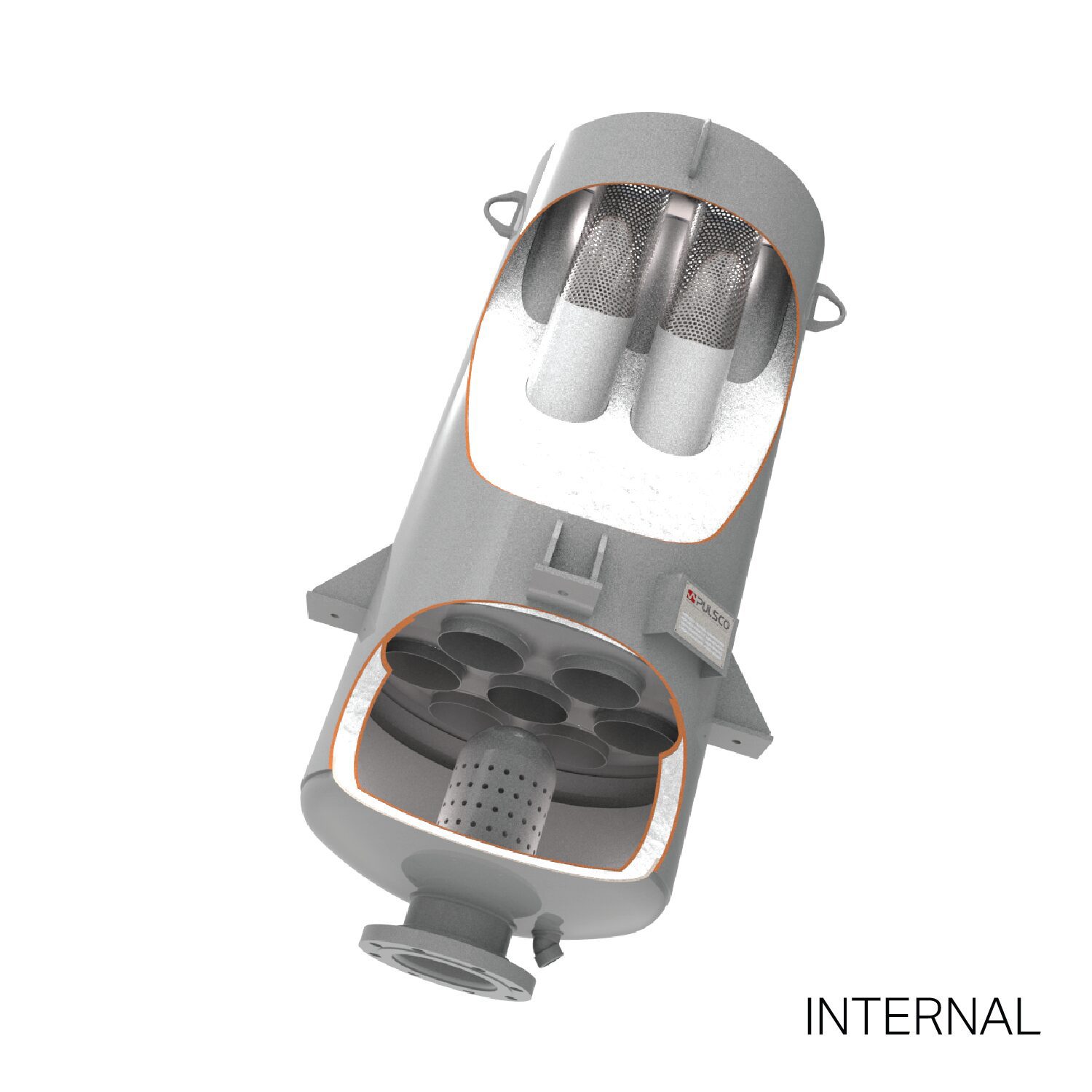

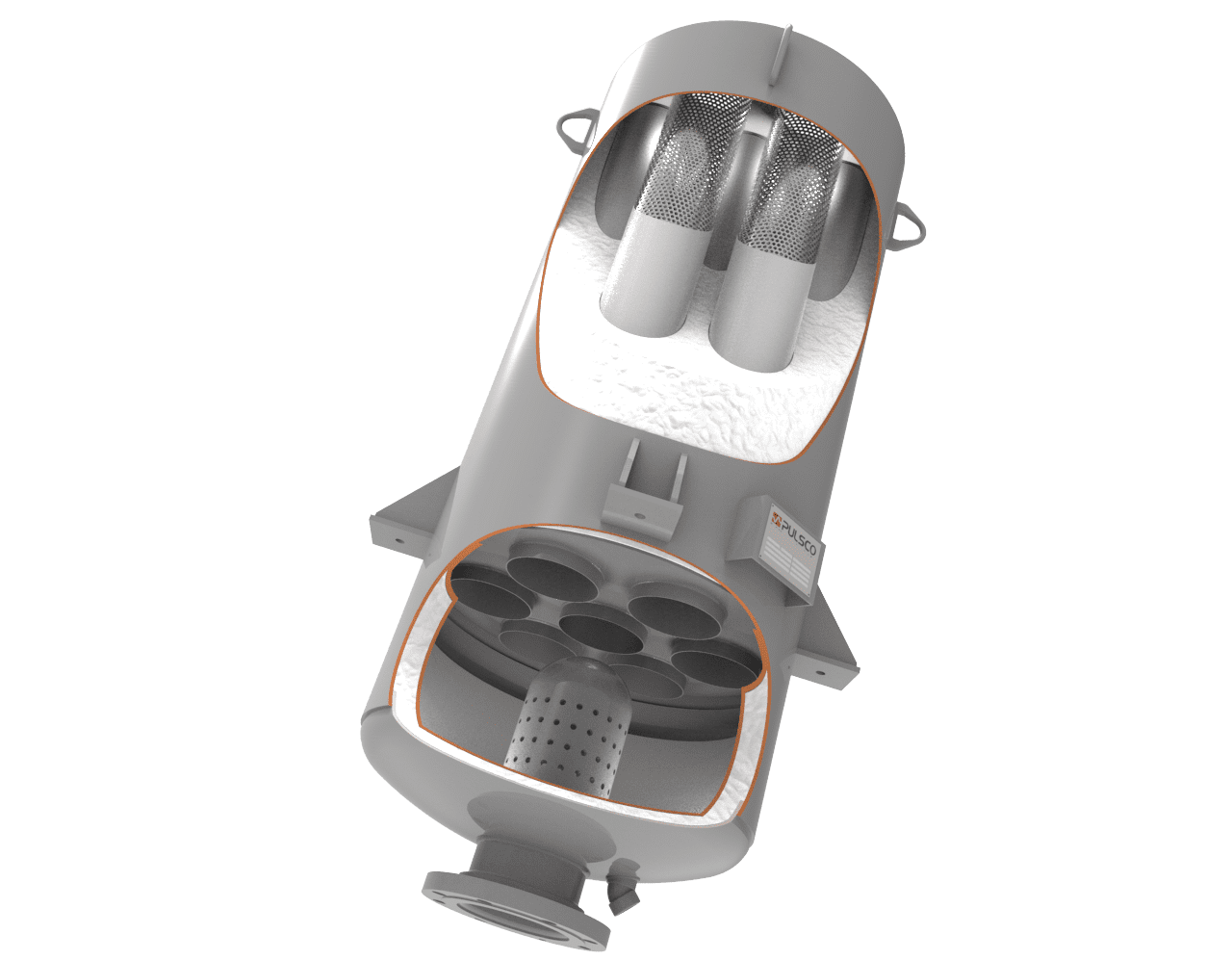

Vent Silencer Operation

PULSCO’s Vent Silencers have a custom pressurized inlet diffuser that shifts the noise spectrum from a low frequency to a more easily attenuated high frequency range. The high frequency noise expands into the plenum and then passes through the tube module where the noise is absorbed by acoustic packing and vented to atmosphere.

Inlet Diffuser

A self-supporting bottom inlet provides energy dissipation and modification of the noise spectrum for easier attenuation. It also provides the back pressure required for optimum valve performance and size.

Plenum Section

The Plenum Section minimizes shell noise radiation and noise leakage.

Acoustic Tube Module

Multiple flow tubes surrounded by acoustic packing, absorb and attenuate the high frequency acoustic energy as modified by the inlet diffuser.

Vent Silencer Design

At a given set of operating conditions, each Vent Silencer is designed to attenuate the noise level to the required level criteria at a given distance from the silencer.

To comply with government ordinances and protection of employees from excessive plant noise, PULSCO Vent Silencers can be sized to handle a wide range of valve pressures and flow rates to maintain attenuation of noise level throughout the system flow range to a required decibel criteria. These criteria are at a specified distance from the silencer and are dependent on the

Flow rate

Temperature

Pressure of the system

PULSCO Vent Silencers are typically fitted with a bottom inlet nozzle. Connection location is flexible by using a skirt support and mounting ring, thereby allowing the silencers to be adapted to those special applications which require a side inlet. To provide capacities for a wide range of flows, our standard Vent Silencers are available in diameters from 12 to 144 inches.

Silencer components are generally constructed from carbon steel. However, they may be constructed from other materials to meet specific design or application requirements such as high temperature, corrosive environment, or oxygen service. Material recommendations are dependent on the specified operating conditions.

For a corrosive environment, components or complete silencers can be constructed from a 300 Series Stainless Steel (usually 304 or 316). For oxygen service, Monel or a Monel/300 series steel combination is usually used together with special cleaning and degreasing procedures.

Fabricated materials and finishes used for Line Silencers are determined by the specified operating conditions. At elevated temperatures exceeding 800° F, PULSCO establishes the silencer design as a “Special Design”. This requires particular attention to the design of the diffuser and may require all stainless-steel construction, special packing and extraordinary erosion protection.

-

Economical high temperature black paint is available for temperatures above 800° F.

-

Zinc rich primer (Carbonline Carbozinc 11) is standard with our silencers.