Often times users are unsure of the problems inherent in their fluid transport systems.

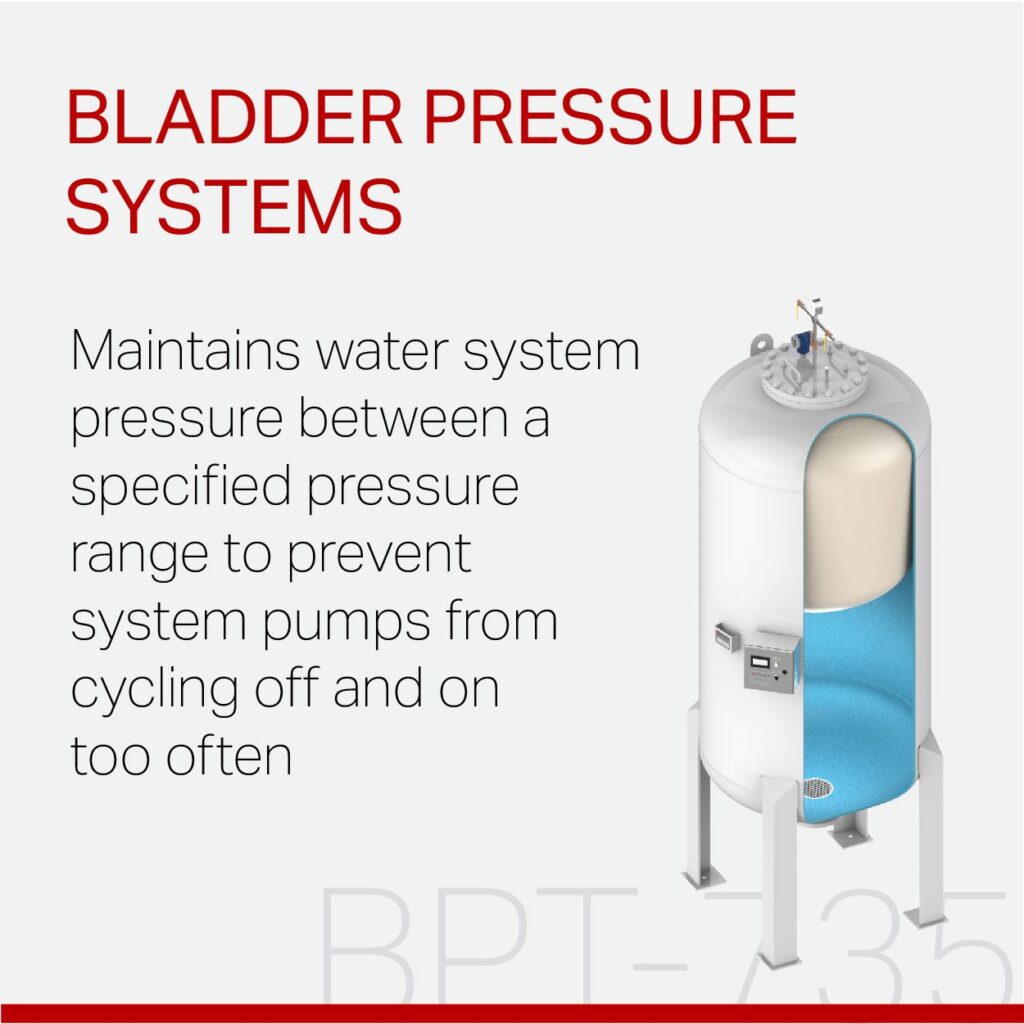

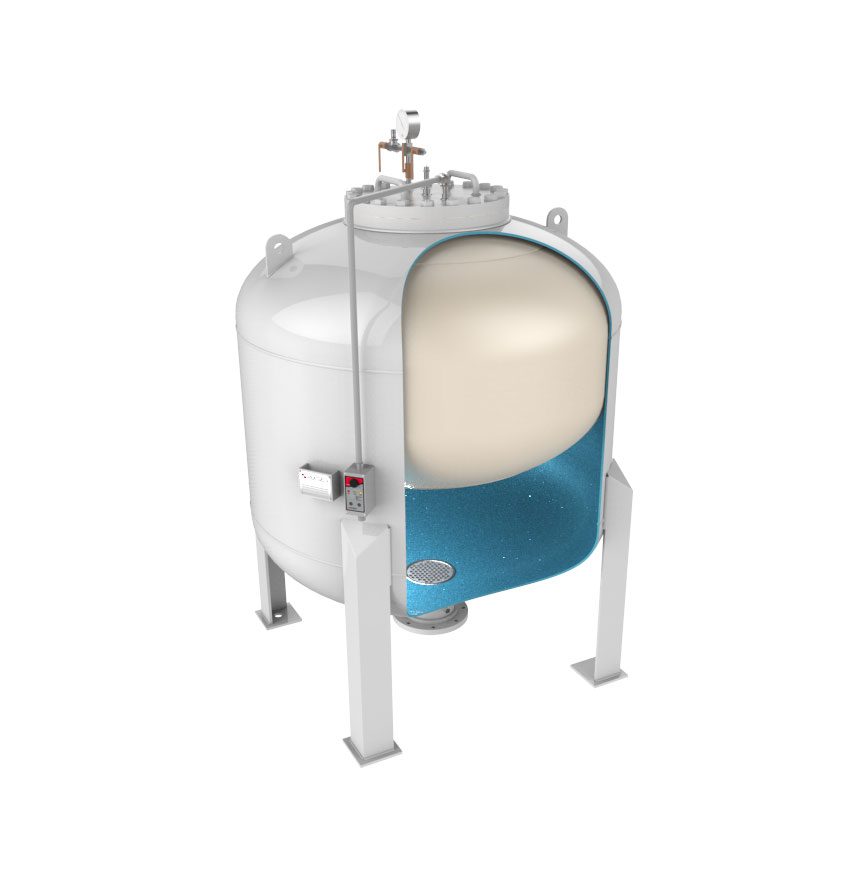

Bladder and Air-Over-Water Control Systems solve an array of fluid transmission and delivery challenges. Water Hammer, also referred to as surge or shock, is a pressure transient event that is caused by sudden changes in flow conditions. These damaging shock waves and pressure transients are often due to pump start up, sudden pump shut down or valve closures.

PULSCO works with its customers to determine the best system to meet their needs. We account for dependability, safety, and cost efficiency for our surge suppression and pressure control systems.