PULSCO’s Liquid Pulsation Dampener is designed to provide the best attenuation of pulsation, vibration, and noise in hydraulic systems. It offers a simple, economical method of pulsation control for hydraulic systems with positive displacement pumps regardless of operating pressures and flow rates.

The high frequency component of the pressure pulse is generally the primary cause of damaging pipe vibrations. Several configurations of acoustic elements can be utilized to reduce the resultant pressure pulsation.

Call us 949.261.1717

For any question or concern

Features

High Pulsation Reduction

The LPT provides greater than 90% reduction in pulse amplitude, regardless of operating pressure, at frequencies of 100Hz and higher under typical operating conditions resulting in increased system efficiency.

Reduced System Maintenance Cost

Repair or pipe and fitting replacement in the hydraulic system is virtually eliminated due to reduced pulsation and vibration in the piping system.

High Noise Level Reduction

Pipe radiated noise is reduced by 20dB or more. The LPT provides a quieter environment for hydraulic system operations.

Improved Particle Filtration

Pulsation reductions provide for a more stable filter media and particle filtration efficiency.

Zero Maintenance

The LPT has zero moving parts and does not require spare parts. Maintenance and tuning, unlike pressure charged dampeners, is never required.

Design

PULSCO Liquid Dampeners can be designed using any material, in any thickness to compensate for temperature, pressure and flow conditions.

PULSCO’s Liquid Dampeners range in size from 1 to 24 inches in diameter and 4 to 72 inches in length. The diameter and length, as well as the inlet and outlet configuration can be varied to meet specific installation situations.

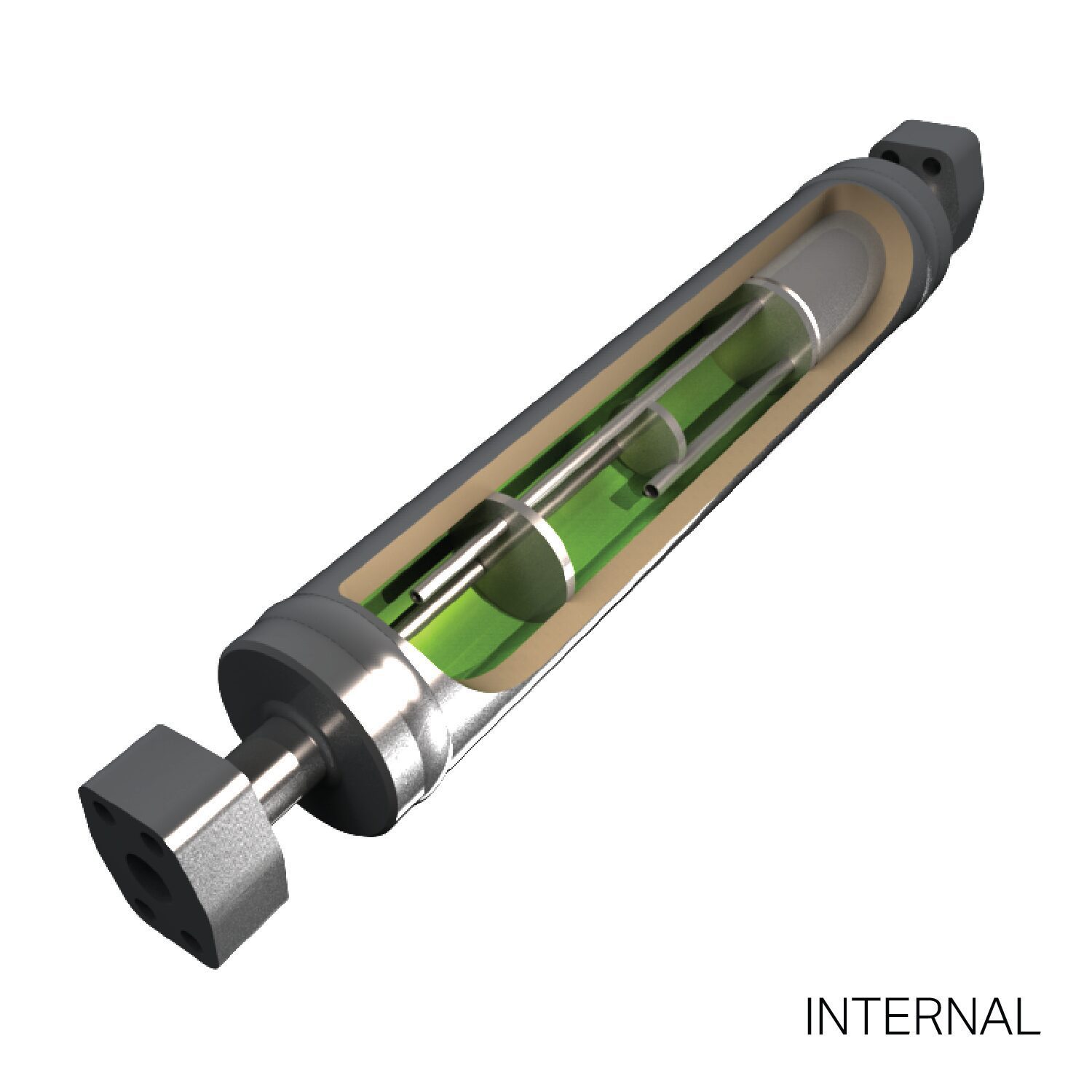

The most prevalent style used by PULSCO for higher frequency hydraulic systems is the three-chamber device. This design features a chamber divided into three compartments connected by series and branch tubes. The specific design, however, is dependent on the unique application and desired attenuation.

Application

Liquid Dampeners have been developed for commercial and military aircraft to diminish hydraulic line pressure pulsations and reduce noise for increased passenger comfort and improved operational characteristics of flight control surfaces.

Additionally, the range of use for PULSCO Liquid Pulsation Dampeners is highlighted by applications such as silencing wine processing lines at Foster Farms®, and drastically reducing the noise emanating from the hydraulically powered set at the Cirque du Soleil®, Treasure Island Show at the Mirage® Las Vegas.

Industrial machinery employing hydraulic power supplies including injection molding equipment, machine tools, lifts, construction equipment and all types of hydraulic moving devices have benefited from PULSCO Hydraulic System Pulsation Dampeners.

Typical applications for PULSCO’s Liquid Pulsation Dampener are:

Military & Commercial Aircraft

Naval & Marine Vessels

Offshore Platforms

Refineries & Process Plants

Water injection Pumps

Operation

PULSCO’s Liquid Pulsation Dampeners use the acoustic properties of specifically arranged volumes and tubes to form a reactive low pass filter. All hydraulic motors and pumps generate pressure pulsation at frequencies related to the system speed and configuration.

The pulsations propagate through the fluid column within the hydraulic lines, and are the root cause of radiating airborne noise and even system failure due to vibration. The LPT consists of a network of tubes and chambers acoustically tuned to dampen these pulsations in the targeted frequency range, thus reducing vibration and noise.

Preferably installed in close proximity to the pump outlet, the LPT may be mounted in any position.